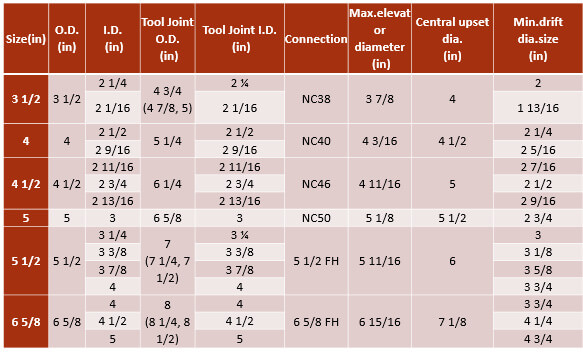

The drill pipe has two tool joints, one female is called a box and the other male is called pin. The outer diameter of the tool joint is larger than the body of the drill pipe to accommodate the threads.

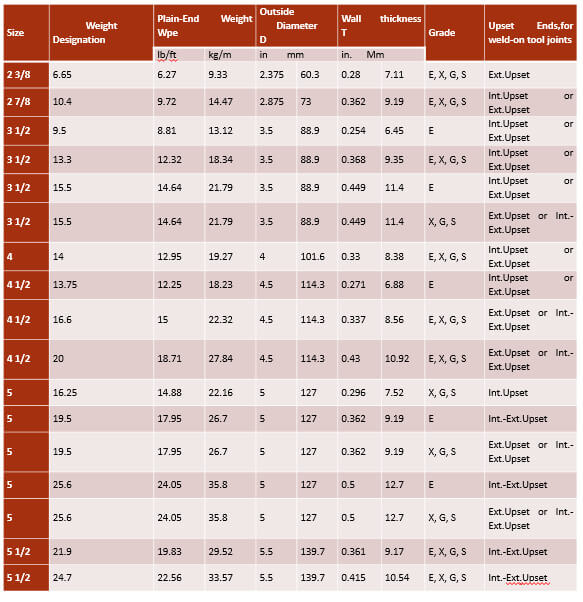

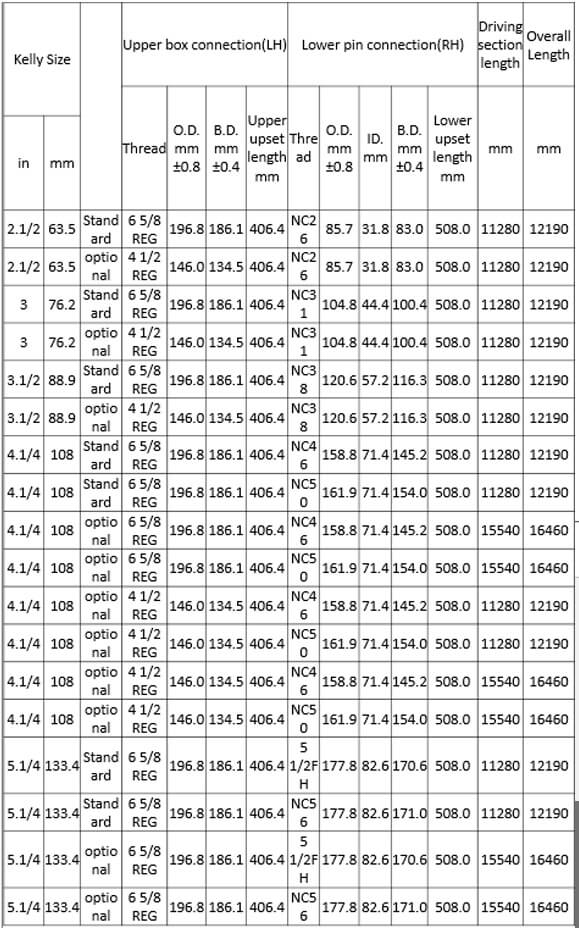

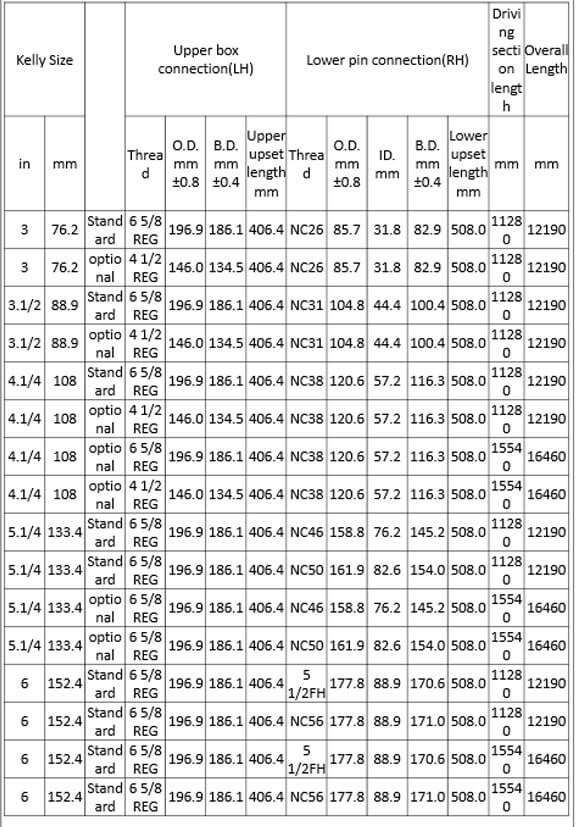

One drill pipe is called a single or a joint. The dimensions of the drill pipe are specified by the API (American petroleum Institute). There are three ranges of length; range 2 is most common on rig sites. The drill pipe must be measured on rig site to get accurate length of drill pipe. The drill pipe is manufactured in verity of weight, diameters and also materiel grades.

The drill pipe is characterized by burst, collapse, tensile and torsional strength. These specifications are used to select the appropriate drill pipe for a particular drilling operation.

The weight of the drill pipe mentioned in the manual is called weight in air. When drill pipe is in the well, it has to be taken in consideration the buoyancy force which is related to density of the drilling fluid. The weight of the drill pipe when run in the well can be calculated as follows:

Buoyant weight= weight of pipe in air x buoyancy factor

Drill pipe stress and failure:

The drill pipe can be exposed to many stresses:

Tension: due to hole problems, an over pull can be exerted causing extra tension on the drill pipe (ex: stuck pipe). This tensile load can lead to drill pipe failing.

Torsion: Bad hole conditions can increase the twisting force and torque on each joint leading to poor rotation transmission from the surface to the bottom.

Cyclic fatigue: The wall of the drill pipe while drilling deviated wells is exposed at point of bending to tensile and compressive forces. While rotating the drill string, the same point on a drill pipe sustains a cycle tensile and compressive forces. This cyclic stresses can result in fatigue of the drill pipe.

Also there are other causes of fatigue like abrasive friction, vibration and bit bouncing off bottom.

Corrosion is also another issue which can affect drill pipe strength; corrosion can be due to presence of dissolved gases and acids. Carbone dioxide can form acid dioxide which can lead to steel corrosion.

The hydrogen sulfide can be present in the formation. It can cause hydrogen embrittlement or sulfide stress cracking. The surface of the steel absorbs the hydrogen in the presence of the sulfide. When the concentration will be greater than a certain level (less than 13 ppm), cracks can appear on pipe body. The combinations of stress and cracks leads to pipe failure.

Tool joints:

The tool joints provide screw threads in order to connect drill pipes together. The seal is guaranteed by the shoulder/shoulder connections between pin and box. Hard facing material is welded on the surface to protect the tool joint from abrasive wear when rotating drill string in the borehole or when making connection by rig tongs. This layer of hard facing material can be replaced in workshops when it becomes depleted due to excessive wear. The internal diameter of the tool joint is less than the internal diameter of main body. The same stresses applied on the drill pipe during drilling operations are subjected on the tool joint, but also there are other additional issues:

- During operations, frequent engagement of box and pins can be done harshly which can damage the threads.

- When tripping out of the hole, the last tool joint support all the weight of the string beneath it.