• Extrusion is a process that converts raw material into a product with desired shape and form by forcing the material through a small opening using pressure

• The process involves a series of unit operations such as mixing, kneading, shearing, heating, cooling, shaping, Homogenization, Thermal cooking, Degassing, Dehydration, Expansion and forming.

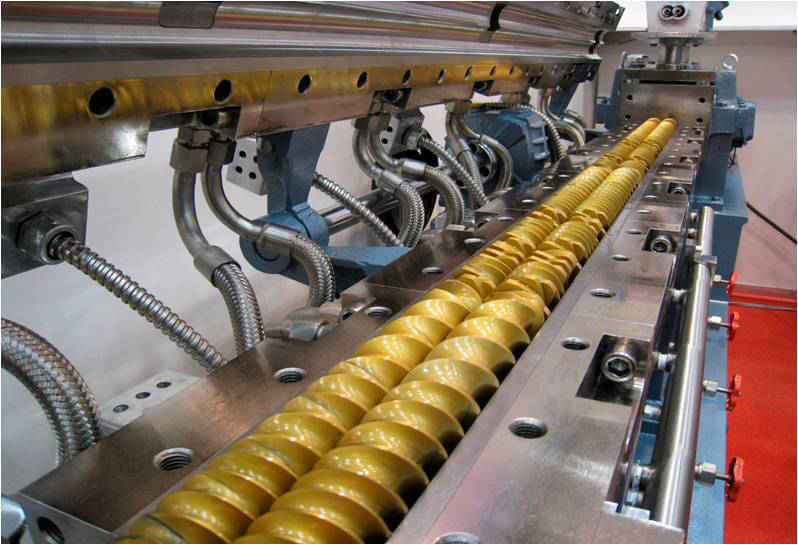

• Extrusion systems can be divided into four different categories based on two different methods of operations: (— cold extrusion or extrusion cooking) and two different barrel configurations: (— single or twin screw).

• Both barrel configurations may be used for either method of operation.

Cold Extrusion

• Cold extrusion is used most often to form specific shapes of extrudate at locations downstream from the die. In this process, the extrudate is pumped through a die without the addition of external thermal energy.

Cooking Extrusion

• When thermal energy becomes a part of the extrusion process, the process is referred to as extrusion cooking.

• Thermal energy may be added to the extrudate during the process from an external source or may be generated by friction at internal surfaces of the extruder in contact with the extrudate.