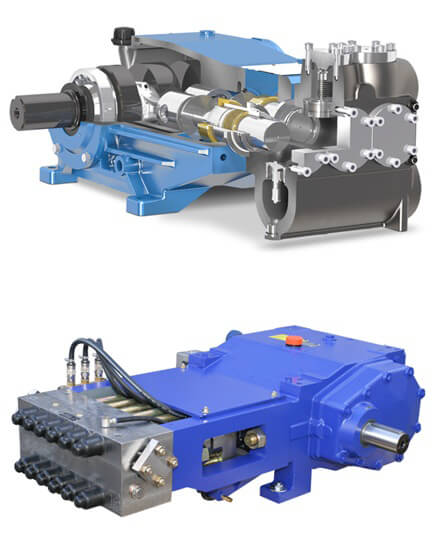

• Flows up to 200 m3/h.

• Maximum system pressures of up to 571 bar or 8,282 PSI

• Power of up to 550kw

• Speeds of up to 420 RPM

• Conforms to all the latest quality standards including API 674, ISO9001/2000, ATEX, NACE, EC P.E.D., Norsok and Gost

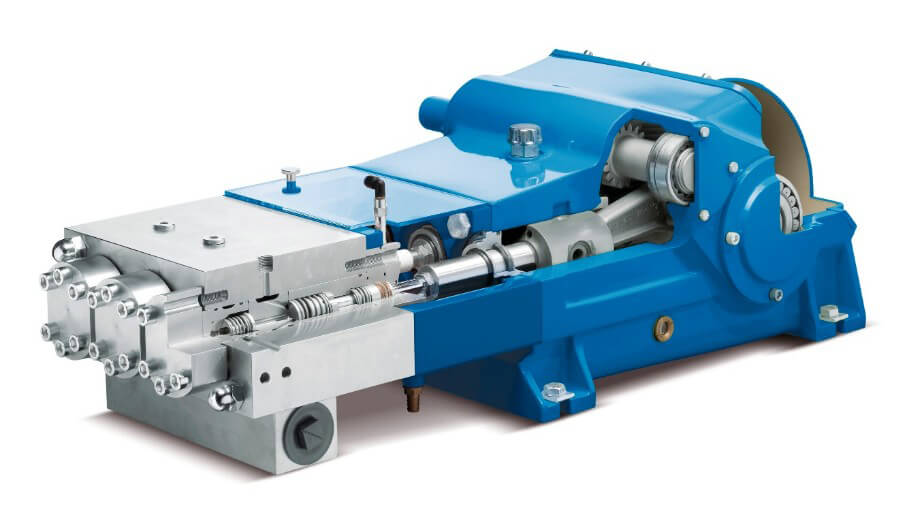

• Crankcase design with special built-in motor support mounting. Providing the option of installing the motor overhead to keep both the footprint and weight to a minimum.

• A range of liquid end materials are available including 316 stainless steel, 22% Duplex, 25% Super Duplex and Inconnel 625. Providing complete compatibility with pumping media.

• Special pressure-formed, braided, PTFE impregnated, Offering exceptionally long life and a wide range of liquid compatibility.

• Packing’s housed in packing cylinder. Assuring proper alignment and optimum life.

• Cylinders are specially surface treated for abrasion resistance.

• Spheroidal graphite iron crankcase. Offering exceptional strength, vibration dampening and flame and spark resistance for added protection in hazardous areas.

• Various cylinders diameters available. Allowing for a wide range of performances to best suit the application.

• Standard splash crankcase lubrication with optional pressure lubrication system

• Modular design

• Customized builds available to suit individual client’s specification