The Purpose of the isolation joint is to prevent detrimental electro-chemical interaction and improve the effectiveness of the cathodic protection system. Isolating joints are also used to ensure effective current distribution for cathodic protection system.

Isolating Joint Functional Requirements:

• Isolation joint shall be suitable for Pigging Operation.

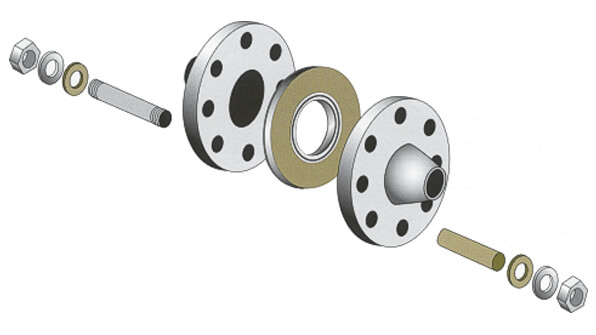

• Slip-on Flanges shall not be used.

• The isolation joints shall be able to withstand the operating conditions stated in the requisition sheets. Where the operating conditions are not stated, the following operating conditions shall apply.

• Installation: Above ground

• Design temperature: 82 deg C maximum & 5 deg minimum

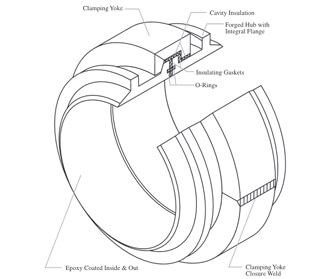

ISOLATION JOINT COMPONENTS:

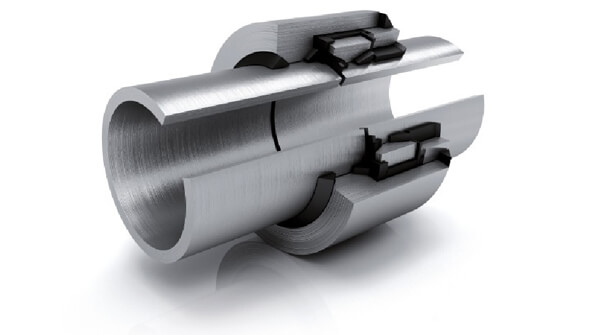

1) Two spools, each consisting of a pipe segment with a bevelled end for welding to the pipeline on one side, having a welded-on boltless flange at the other end for encapsulation into isolating and filler material.

The material used for the pipe segments shall be compatible with the pipeline material.

2) A rigid casting (retaining ring) for strength connection.

– One set of ring seals for pipeline internal pressure containment below 50 bar(g).

– A double sealing arrangement shall be specified for design pressure in excess of 50 bar(g).

3) Two terminal connecting lugs on the outer surface of each spool. Each lug shall be suitable for M10 bolted cable connection.