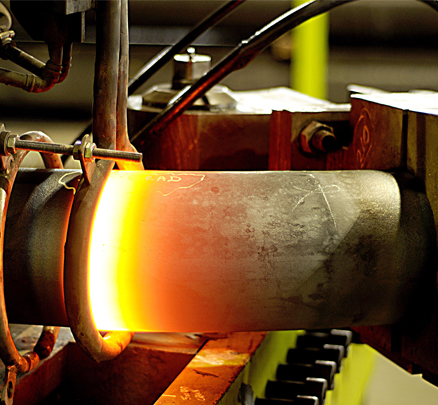

The production of high-quality bends depends on the manufacturing process of the steel pipe that is transformed into the bend.

Obtaining the most suitable chemical composition is also important as this enables the recovery of the pipe’s material properties following the bending process. Depending on pipe dimensions, grades and final bending conditions, alloying elements can be added to the steel in order to guarantee the required hardness and mechanical properties and to ensure that the bend’s chemistry matches as much as possible the line pipe’s chemistry.

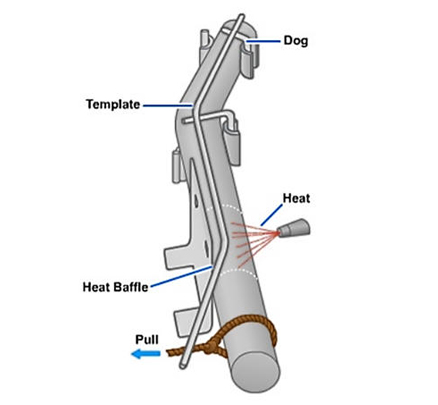

Heat treatment is carried out on each bend in order to achieve the required mechanical properties after bending. For critical applications, such as high-strength steel, heavy wall, sour service or low-temperature, we also perform full quenching and tempering after bending, as a preferred process.

Machining of the bend ends guarantees optimum tolerances of inside diameters, as we ensure the bend has at least the minimum working tolerances of the mother pipe.