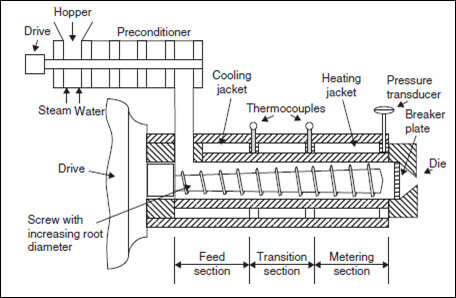

A single-screw extrusion system has three sections.

• Feed section, where the various ingredients are introduced and initial mixing occurs. The rotating action of the screw moves the ingredients to the transition or compression section.

• Compression or transition section, where the ingredients begin the transition to the extrudate as pressure and temperature begin to increase. As the dimensions of the flow channel decrease, the material is compressed and mechanical energy is dissipated as temperature increases. This section may be referred to as a kneading section, with significant changes in the physical and chemical characteristics of the ingredients occurring.

• Metering (or cooking) section, where additional compression of the extrudate occurs as a result of additional reductions in the dimensions of the flow channel and increased shearing action. In some designs, the overall dimensions of the barrel are reduced as well.