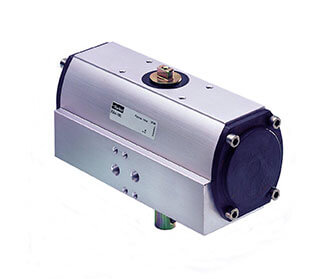

Pneumatic and hydraulic scotch-yoke valve actuators have been designed specifically to guarantee long cycle life in the most demanding applications and environmental conditions. A fabricated steel frame, coupled with an all-steel construction, results in lighter and more corrosion resistant scotch-yoke valve actuators than traditional designs employing castings

Application:

Automation of any quarter-turn mechanism; including ball, butterfly & plug valves and louvers & dampers.

Operating Ranges

2.7 to 12 Barg (40 to 174 psig)

Supply Pressures

13 to 250 Barg (189 to 3,625 psig)

Torque Outputs

200 to 680,000 Nm (1,770 to 6,018,000 lb in)

Temperatures

Ultra-low: -65 to +80°C (-85 to +176°F)

Low: -45 to +60°C (-49 to +140°F)

Standard: -20 to +80°C (-4 to 176°F)

High: -20 to +140°C (-4 to +284°F)