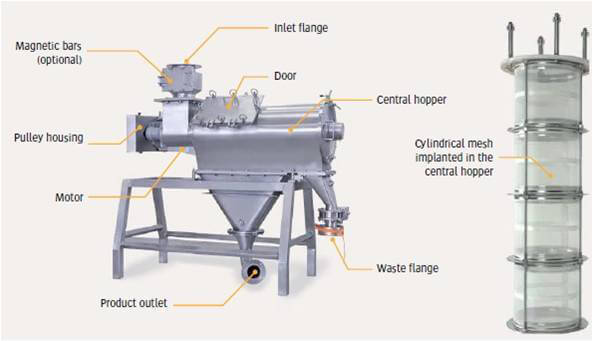

Centrifugal Sifter:

• The Centrifugal Sifter is especially useful with very fine powders.

• Use a vertical cylindrical sieve with a high speed rotor inside the cylinder, so that particles are thrown outwards by centrifugal force.

• The current of air created by the movement helps sieving.

• Sifters are the preferred solution for:

• Policing and scalping of Raw Materials after discharge from paper sacks, boxes, “big bags”, IBC’s and bulk storage silos.

• Two-part classification and separation.

• De-dusting - removal of fine particles from main product mass.

• Re-claiming materials after de-packing.

• Final security screening before packing or bulk out-loading.

• De-watering - separating solids and liquids.

• In-Line sifting (Blowing or Vacuum Systems)

Advantageous of Sifter:

• Low noise levels

• Low plant area with high output

• Low power consumption

• No vibrations

• High efficiency

• Robust compact construction

• Easy clean

• Ease of screen inspection

• Adjustable paddle blades

• Range of machine types, sizes and finishes to suit most sifting applications

• Range of sieve materials

• Excellent inspection and cleaning access

• Easy shaft removal using standard tooling

• Improved basket design with built in tension and length adjustment

• Air regulation assembly

• ATEX certified from safe area to zone 20 internal 21 external

• Bespoke designs:

○ Pressure rated

○ In-Line (positive pressure or vacuum conveying)