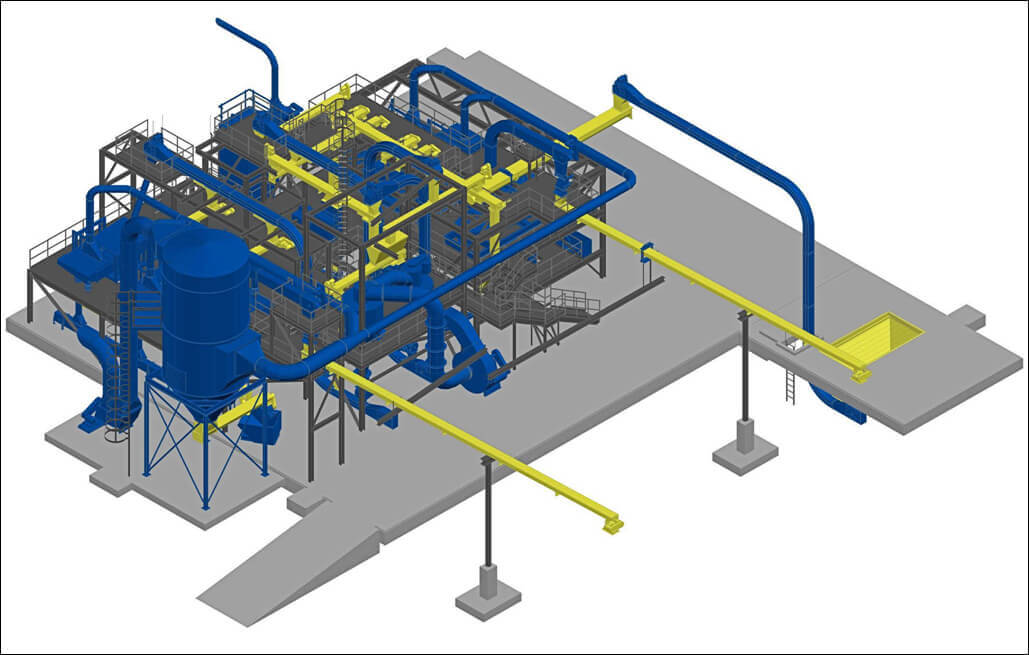

Applications:

Type it please

The advantages of Screw Conveyors:

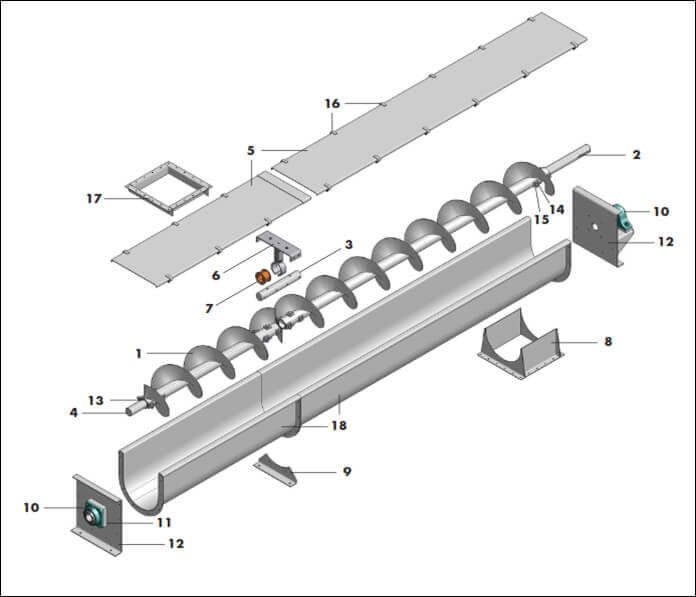

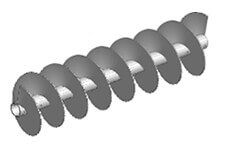

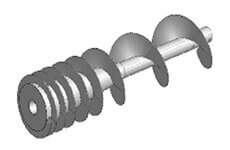

• Screw Conveyors are compact and easily adapted to congested locations.

• They can be used to control the flow of material in processing operations which depend upon accurate batching.

• Screw Conveyors are versatile and can be employed in horizontal, inclined and vertical installations

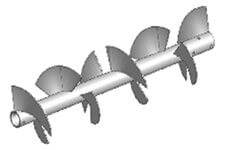

• They can be used as a mixer or agitator to blend> dry or fluid ingredients, provide crystallization or coagulant action, or maintain solutions in suspension.

• They Operated at positive as well as negative pressure

• They can be sealed to prevent the escape of dust or fumes from inside the conveyor; or keep dust or moisture from entering from outside the conveyor.

• They can be jacketed to serve as a dryer or cooler by running hot or cold water through the jacket.

• They can be made out of a variety of materials to resist corrosion, abrasion or heat, depending upon the product being conveyed.

They can be outfitted with multiple discharge points.