You can rely on our expertise and value oriented approach to deliver assured production efficiencies and long-term performance reliabilities to solve your extrusion and compounding challenges.

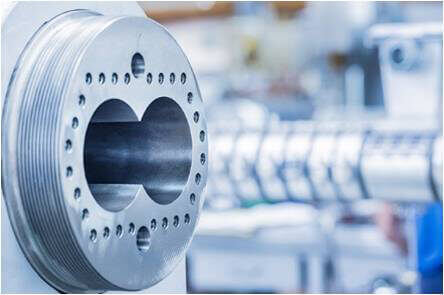

In compounding, various materials are mixed and melted generally in an extruder of some type then pelletized. This pelletized material is subsequently processed into a finished or semi-finished part by either molding or extrusion. Most compounding is done on twin-screw extruders of either co-rotating or counter-rotating design. Other types of equipment, such as single-screw extruders, kneaders and mixers, can also use to compound materials.

Extruders, Pelletizers and Compounding Machines are utilized in many industries like, rubber, plastics, food, Gypsum, Coal, Chemical Powders, Minerals and Ores and etc.

We provide you with a wide range of tailor made products to suit the needs of your particular industry.