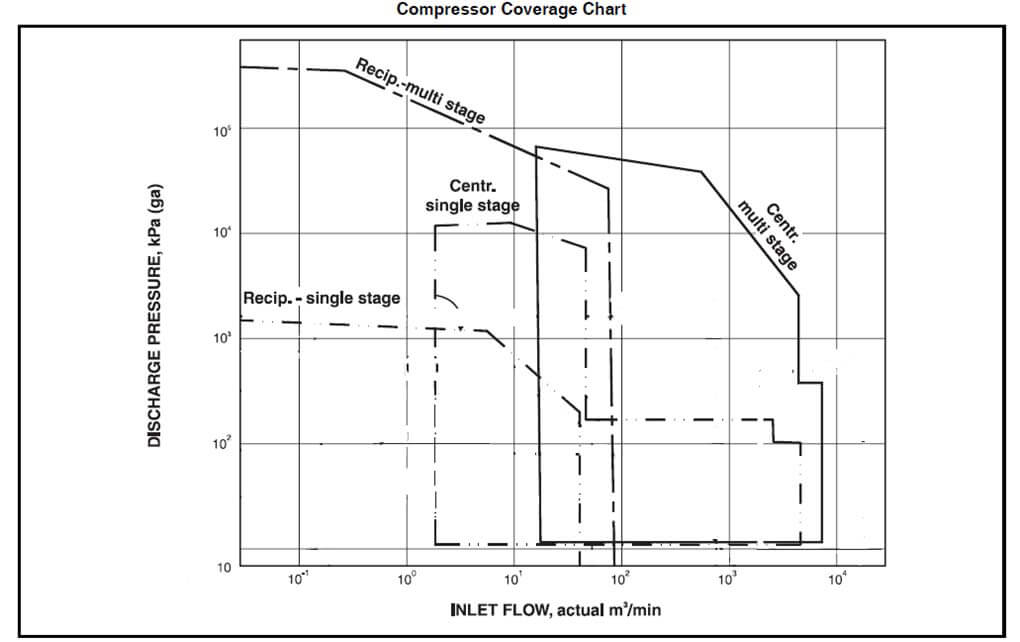

Compressor performance

The dynamic types include radial-flow (centrifugal), axial flow, and mixed flow machines. They are rotary continuous flow compressors in which the rotating element (impeller or bladed rotor) accelerates the gas as it passes through the element, converting the velocity head into static pressure, partially in the rotating element and partially in stationary diffusers or blades.

Reciprocating compressors should be supplied with clean gas as they cannot satisfactorily handle liquids and solid particles that may be entrained in the gas. Liquids and solid particles tend to destroy cylinder lubrication and cause excessive wear. Liquids are non-compressible and their presence could rupture the compressor cylinder or cause other major damage.