The innovative pneumatic blender without any mechanical parts inside the machine is suitable for high abrasive and fragile products. A large amount of product can be blended, more fuel efficient than mechanical blending, versatility and easy cleaning, makes the application of pneumatic blending in different fields possible.

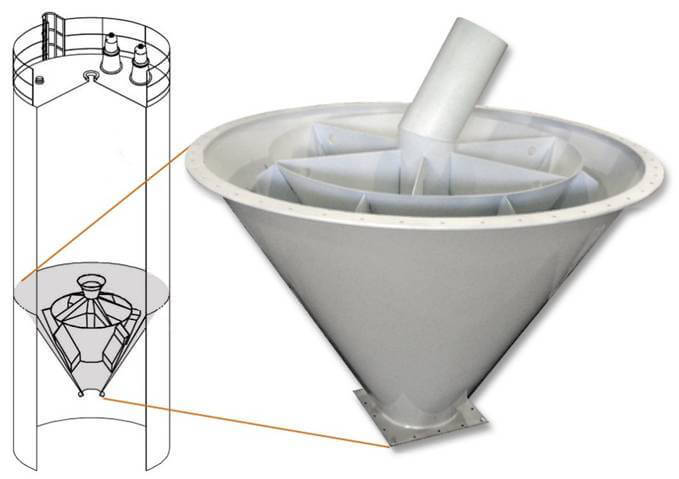

Reliable & Efficient Pneumatic blender, built with few moving parts, blend powders and granulate quickly, cleanly, and efficiently, with consistent results. Equipped with six or twelve wear-resistant aerators mounted around a housing cone, gentle blasts of compressed air are injected into the center of the batch. This action softly lifts materials upward and outward until the blending target is achieved. Adjusting the air pressure, on/off duration, and the number of pulses optimizes the blending action.