HIPPS are designed according to following standards:

IEC 61508: “Functional Safety of Electrical/Electronic/Programmable Electronic Safety Related System”.

IEC 61511: “Functional Safety: safety instrumented systems for the process industry sector”.

ANSI/ISA S84.01: “Application of Safety Instrumented Systems of the Processed Industries”.

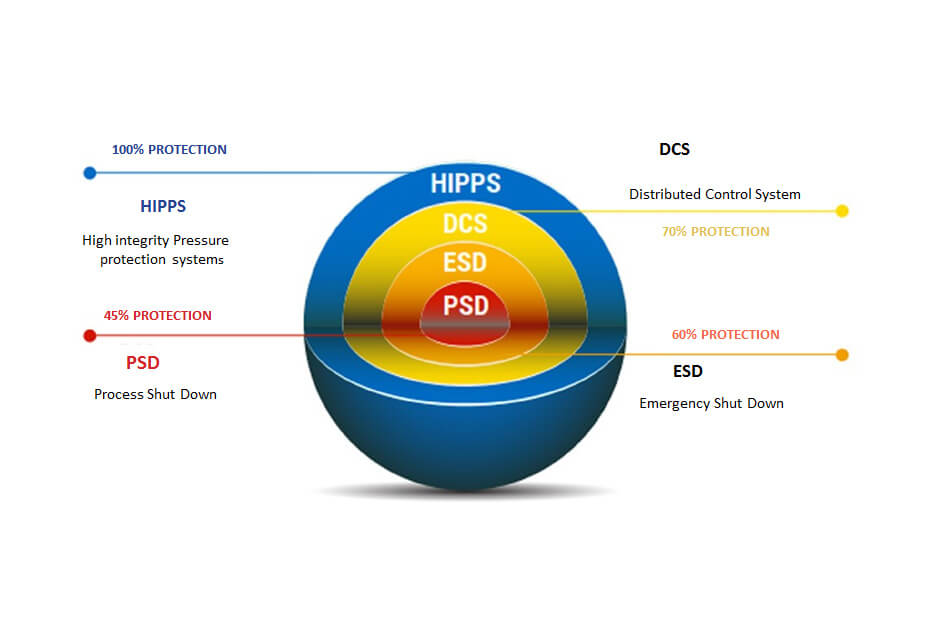

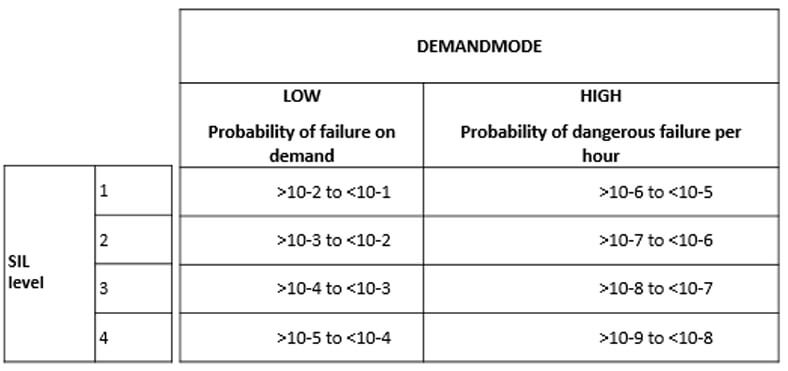

Standards mentioned above are performance based so design of HIPPS is also based on the required Safety Integrity SIL has four categories, from 1 to 4, and it is defined by plant end user by means of making a risk analysis of the p related to the fulfillment of the tolerance risk: this means that SIL level results of the combination of two factors:

Frequency of fail occurrence.

Consideration of the consequences of fail (dangerous failure or safe failure).

Safety Instrumented Function (SIF) defines the level of protection against failure and it is defined by the Probability of Demand (PFD). PFD avg is defined as the average probability of failure the safety function between 0 to 1. Standard defines the maximum allowable PFD avg value depending how often the demand of SIF is:

High demand: safety demand interval shorter than one year.

Low demand: safety demand interval longer than a year.