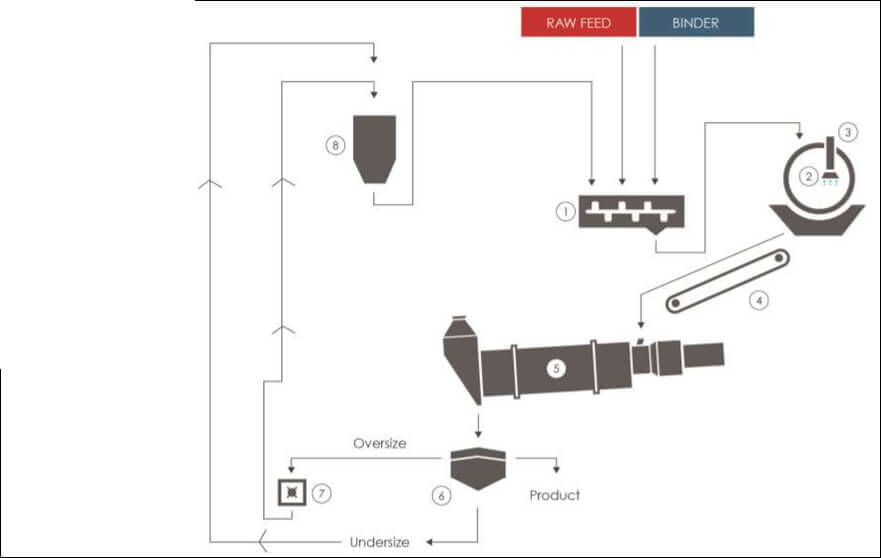

What follows gives an overview of the disc pelletizing process.

In an application using an agglomeration drum, the process would be similar, with only the replacement of the disc with the drum.

Pre-Conditioning

Material fines are first conditioned in a pin or paddle mixer. Not all processes utilize a conditioning step, but in many cases, those that do see many benefits from it, including reduced binder costs, increased production, and an improved product.

Conditioning a material helps to prepare it for optimal pellet formation, and ultimately creates a more refined product.

Pelletization

Once material has been conditioned, it can be fed to the disc pelletizer.

For processes that do not utilize a conditioning step, this is where the process begins.

Material fines and binder are fed onto the rotating disc at a continuous rate. The material fines become tacky through the addition of the binder, allowing them to pick up more fines as they tumble on the disc, similar to rolling a snowball.