ADVANTAGES OF THE SEALLESS CANNED MOTOR TECHNOLOGY:

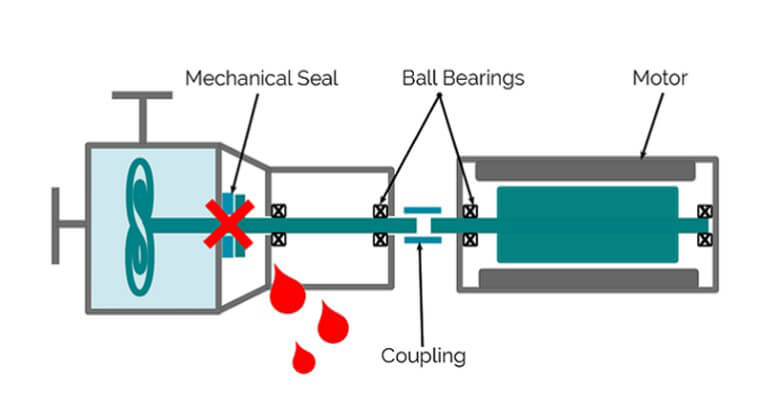

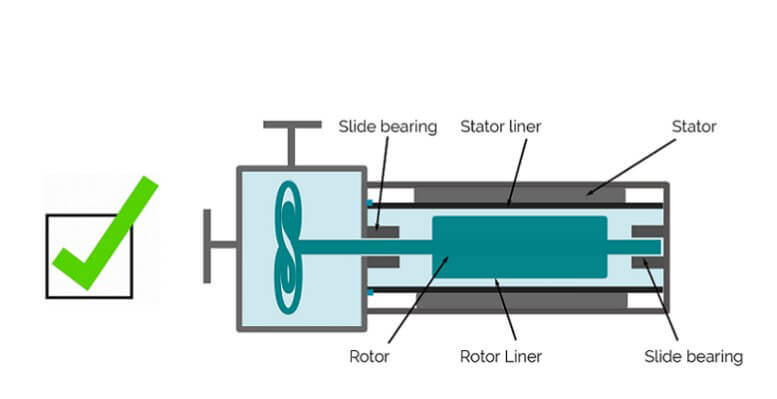

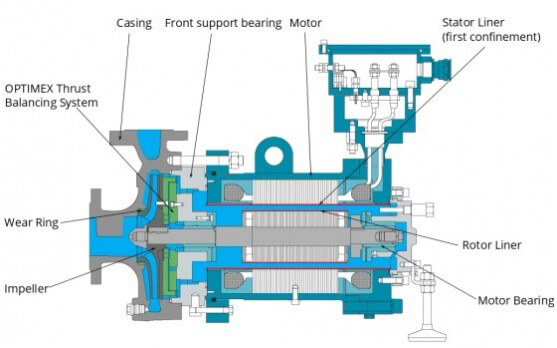

• No mechanical seal = optimal MTBF.

• Low maintenance costs, long running life.

• No expensive and complex lubrication or cooling systems necessary.

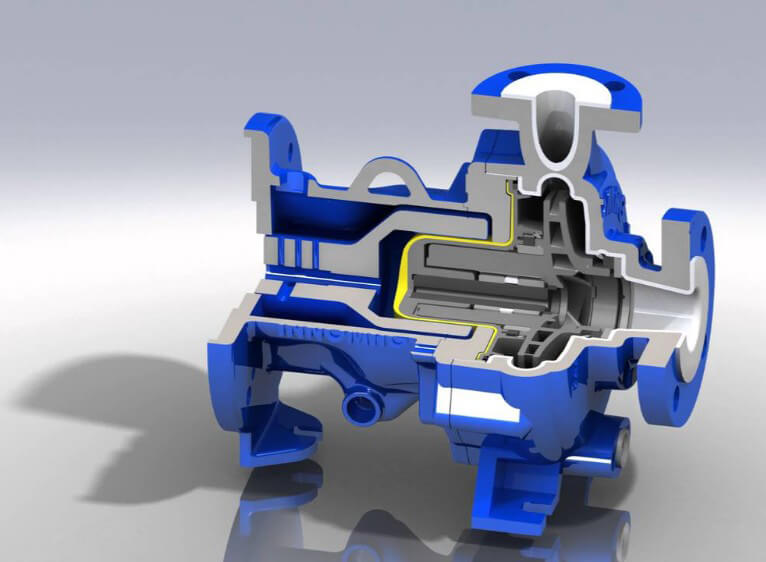

• “One-piece” design = gain of space.

• Low sound level.

• Easy to assemble and disassemble.

• No clamping tie-rod (security in case of fire).

• Interchangeability: a given motor can be adapted on any hydraulic.

• Complete Flushing by the flushing hole, without disassembling the pump.

• Hydraulic balancing of the axial thrusts.

• Automatic degassing.

• Stator liner not submitted to the traction efforts created by the pressure or by differential dilatations.

• Intense circulation of the liquid in the motor, allowing an effective cooling.

• Possibility to install on the pump a liquid presence and/or a temperature sensor.