Composite gaskets are a combination of metal and non-metal material. Different types of combination of materials are possible based on service requirement.

Spiral wound, Metal Jacketed, and Kamprofile gasket are well known in composite gasket category. They are used in a wide range of pressure and temperature services. Composite gaskets are cost effective with compare to metal gaskets but Careful handling is required. Composite gaskets are used on raised face, male-female, and tongue-and-groove flanges.

Spiral Wound Gasket

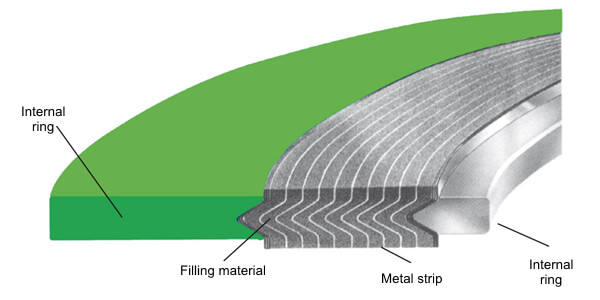

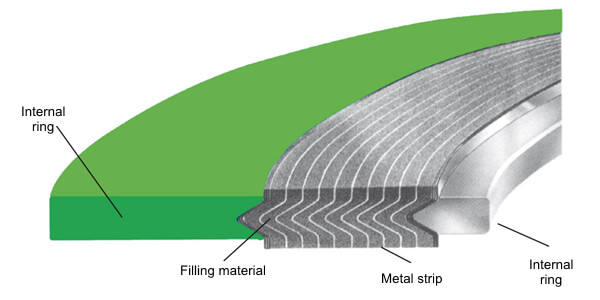

The most widely used composite type gasket is a Spiral Wound Gasket. It is suitable for wide range of pressure and temperature class. Normally Graphite or PTFE used as filler material & stainless steel or other exotic material is used as the winding material.

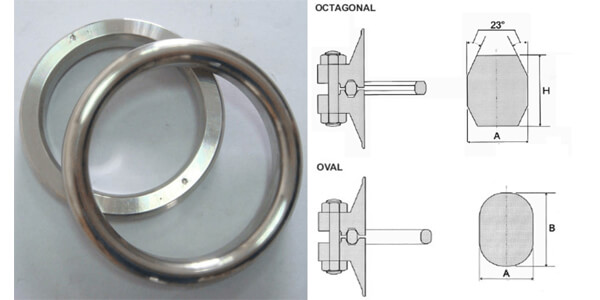

There are three components in spiral wound gasket. Inner & Outer ring, filler material, and winding material. However, sometimes an inner ring is not used. You can see in the image spiral wound gasket with and without inner ring. The inner ring is used to provide additional support to the winding material. The winding is an alternative layer of filler material and winding material. The filler material is a soft material such as graphite and PTFE and winding material is a thin sheet of metal.

Materials:

In a spiral wound gasket, Winding Strips are manufactured from

• Stainless steel material grades such as Type 304,316,347

• Or Exotic material such as Monel, titanium, duplex can also be used as per service requirements.

The filler material of winding can be a

• Flexible Graphite or PTFE depends on of service temperature of gaskets. PTFE is not used for high-temperature services.

Outer Ring of Spiral Wound Gasket mostly manufactured from Carbon steel, whereas Inner ring is mostly manufactured from Stainless Steel Type 304,316,321,347. Or from an Exotic material such as Monel, titanium, duplex etc. These depend on the type of fluid inside the pipe as inner ring is in direct contact with the fluid.

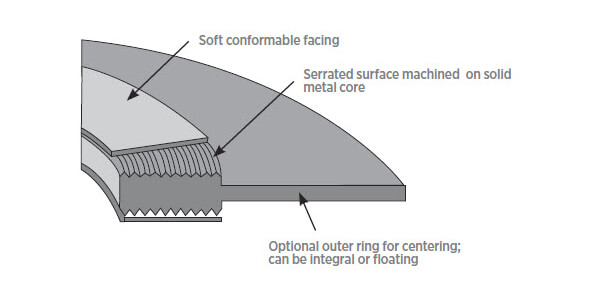

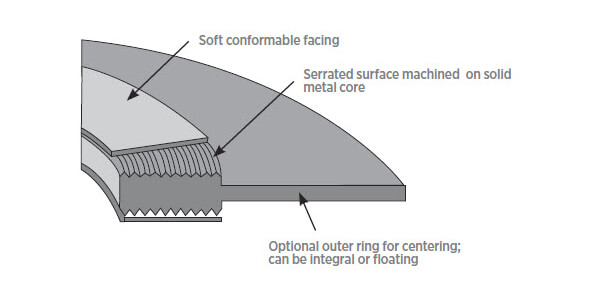

Kammprofile / Campofile Gasket

Kamm/ Cam profile Gasket is having a solid metal core with concentric grooves. Filler material, either graphite or PTFE is layered on this grooved metal ring. It is Costlier than Spiral wound gasket but provides better blowout resistance and easy to handle even in large diameters. Kammprofile gaskets are used in a wide variety of service fluids and operating pressure-temperatures classes from Class 150 to Class 2500 flanges.

Metal Jacketed Gasket

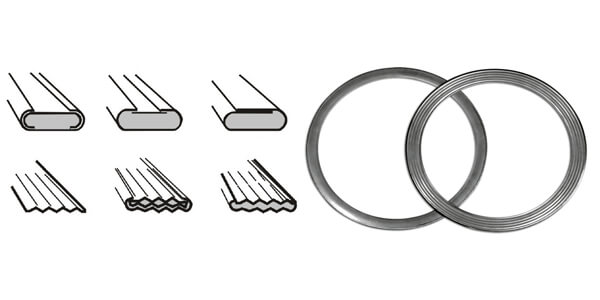

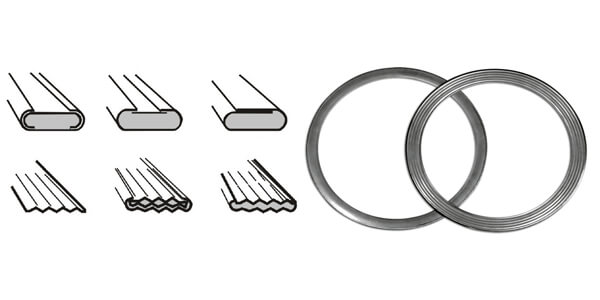

In Metal Jacketed Gasket, the Soft filler material is enclosed in a thin sheet of metal jacket. There are different ways to cover filler material as shown in the image. Jacketed gaskets are easily fabricated in a variety of sizes and shapes and are an inexpensive gasket for heat exchangers, shell, channel, and cover flange joints. Metal jacketed gaskets are commonly used in heat exchangers & valve.

Materials:

Cammprofile and metal jacketed gaskets are manufactured from the same materials that used to manufacture spiral Wound Gasket.