WORKING OF INTERNAL SCREW MIXERS:

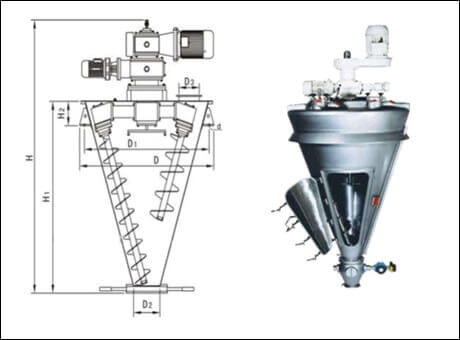

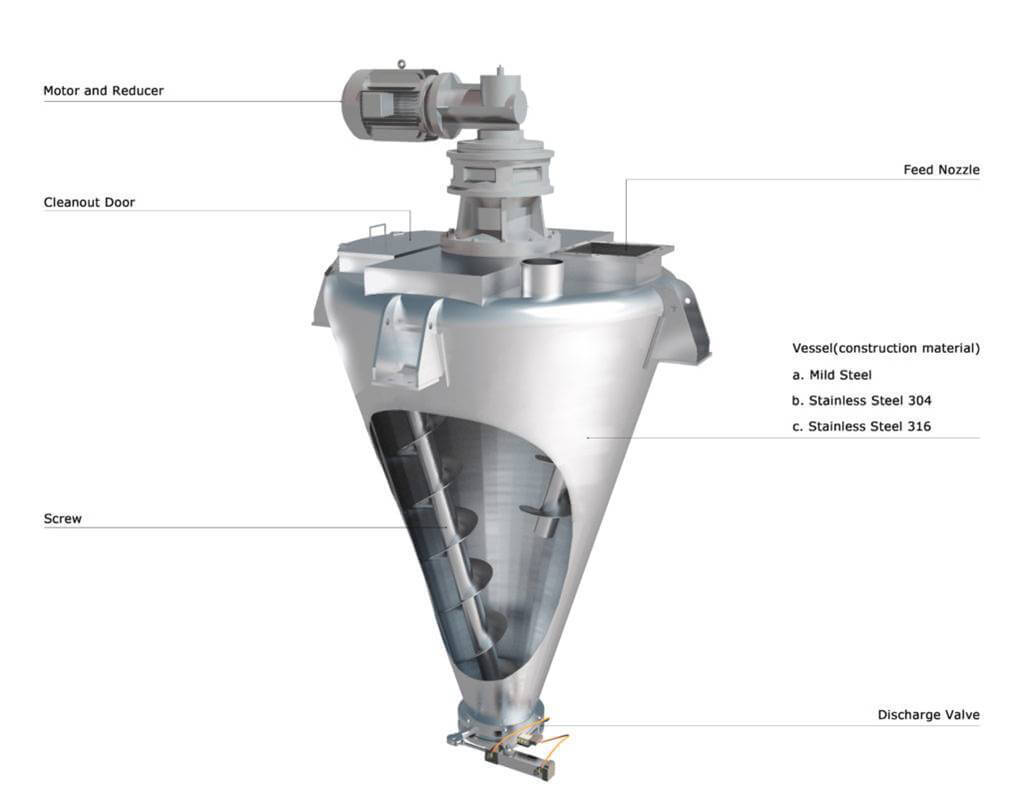

• It consists of a vertical vessel with a screw rotating to achieve the circulation of material and secondly the elevation of material.

• This results in intermixing of solid grains as well as shear action to the ones in contact with the screw or the walls of container.

• The feed enters from bottom usually with aim to nullify the gravity factor which could escape the molecules without desired mixing.

• Two vessel shapes are normally used for this category, the cylindrical and the conical

APPLICATION OF SCREW MIXERS:

• Mixing and homogenization of powders, pastes and slurries

• Granulation or agglomeration of powders

• Addition or injection of liquids into dry powders

• Reaction under vacuum or pressure conditions

• Processing of powders under inert conditions

• Heating and cooling of powders

• Storage of non-free flowing powders

• De aeration or densification of powders

• Homogenization of particle size and color