Selection criteria for pipe fittings:

The pipe fittings “bodies” are most often of the same base material as the pipe or tube in which they are to be connected, e.g., steel, polyvinyl chloride (PVC), copper or other plastic or metal. Besides this, any material that is allowed by a code or a standard can also be used. For example, a pipe fitting made of brass is common in otherwise copper piping and plumbing systems. The materials of construction of pipe fittings must satisfy certain criteria like as follows:

• The material of construction must be compatible with the other materials in the system.

• It must be compatible with the fluids or solids being transported.

• It should withstand fluctuating temperatures inside and outside of the system.

• It should also be compatible with different pressure levels.

• Fire hazards, earthquakes, and other unforeseen factors also influence pipe fitting materials.

• Pipe fitting material specifications and construction are application-dependent.

• For optimization of component selection, user consultation with fitting suppliers is a must.

• The materials of construction should also conform to certain standards like BSP, NPT, ASME, ASTM, DIN, JIS etc.

• Surface finish is equally important. It is to be noted that all pipe fittings should have a proper finish as pipe fittings are constantly in harsh environments. Corrosion resistant property of the materials is an essential requirement.

ASTM International: American Society for Testing and Materials

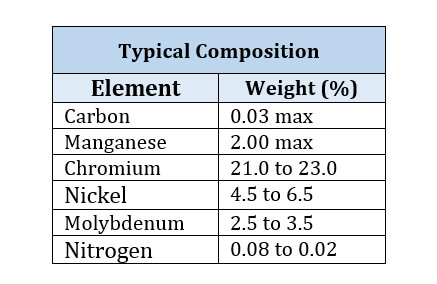

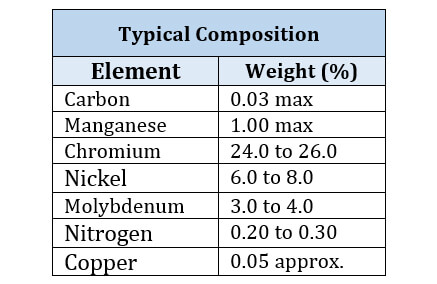

This is one of the largest voluntary standards development organizations in the world. ASTM standards define the specific manufacturing process of the material and determine the exact chemical composition of pipe fittings, through percentages of the permitted quantities of carbon, magnesium, nickel, etc., and are indicated by "Grade". This is a reputed scientific and technical organization that develops and publishes voluntary standards on the basis of materials, products, systems and services. This is a trusted name for standards. The standards covered by this organization covers various types of pipes, tubes and fittings, especially made of metal, for high-temperature service, ordinary use and special applications like fire protection. The ASTM standards are published in 16 sections consisting of 67 volumes.

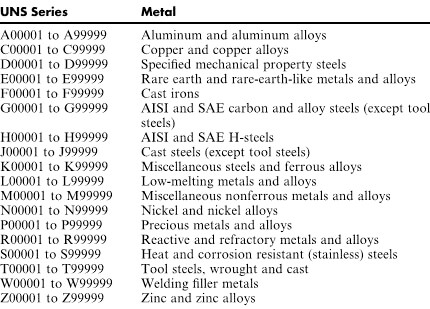

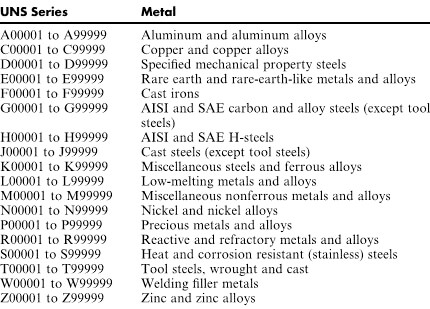

UNS: Unified Numbering System

The Unified Numbering System (UNS) for identifying various alloys is also quoted. This is not a specification, but in most cases, it can be cross-referenced to a specific ASTM specification.

Alloy numbering systems vary greatly from one alloy group to the next. To avoid confusion, the UNS for metals and alloys was developed.

The UNS number is not a specification, because it does not refer to the method of manufacturing in which the material is supplied. The UNS indicates the chemical composition of the material. An outline of the organization of UNS designations follows:

Some ASTM materials are compatible with specifications from other countries, such as BS (Britain), AFNOR (France), DIN (Germany), and JIS (Japan). If a specification from one of these other countries either meets or is superior to the ASTM specification, then it is considered a suitable alternative, if the project certifications are met.