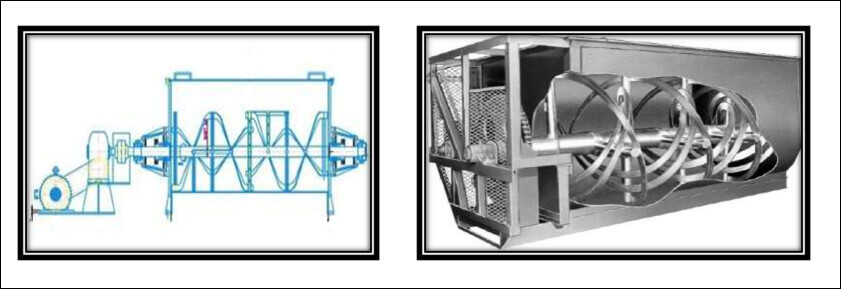

CONSTRUCTION OF RIBBON BLENDERS:

• A ribbon blender consists of a U-shaped horizontal trough containing a double helical ribbon agitator that rotates within.

• The agitator's shaft is positioned in the center of the trough and has welded spokes on which the helical ribbons (also known as spirals) are welded.

Working of ribbon blenders:

The charging of material in the blender is generally through nozzles or feed-hoppers mounted on the top cover of the blender. The inlet cover also provides maintenance and cleaning access to the inside of the blender.

An external jacket can also be provided on the blender container for applications which require heating or cooling of product material.

A spray pipe for adding liquids can be mounted above the ribbons.

For materials that tend to form agglomerates during mixing, high speed choppers can be provided for disintegration of the agglomerates.

APPLICATIONS OF RIBBON BLENDERS:

The following are the applications of the Ribbon Blender:

Blending large volumes of dry solids.

Dry powder to wet phase mixing.

Mixing of bulk drugs, chemicals, and cosmetic powders.

Dry Blending of capsule formulations.

Lubrication of dry granules in large quantity.

Heating, cooling, and drying of materials.

Coating solid particles with small amounts of liquids to produce formulations.

Materials commonly blended in the ribbon blender are as follows:

Abrasives, Engineered plastic resins, Pesticides and herbicides, Animal feeds, Epoxy resins, Pet foods, Bakery premixes, Carbon black.