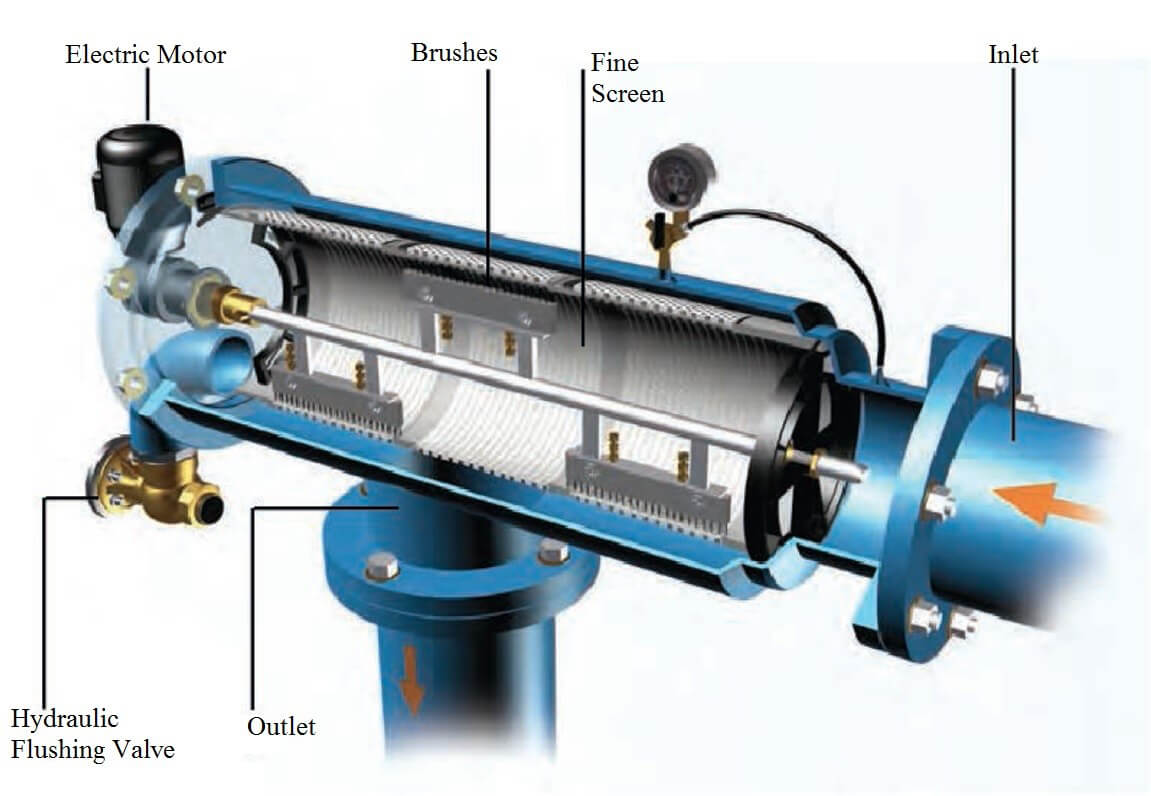

This process is managed by an automatic control system that starts and stops an electric motor which opens and closes the automatic drain valve. The filter is washed without interrupting the outlet flow.

Application of these filters is includes but not limited to:

• Protect catalyst beds from contamination and plugging by removing coke fines, dirt and other solid contaminants, amines and chemicals.

• Power Plants by removing solid contaminants, naphtha, diesel and etc.

• Seawater intake Units

• Cooling tower filtration

• Desalination plants

To determine the number of filter elements, following process parameters would be specified by the customers:

• Flow Rate

• Solids Content

• Fluid Viscosity

• Allowable Pressure Drop

Our expertize in cooperation with reputable European companies made us able to increasing operating efficiency and production yield in maximum flow rate with minimizing required backwashing sequences.